Bienvenue

Ce qui fait sens, pour nous

– être votre partenaire Moule et Injection

– que vous payez pour des pièces bonnes

– être les premiers à vous seconder

– Quand c’est trop important, il faut essayer

– respecter nos délais tout en pensant « la qualité d’abord »

…depuis plus de 20 ans.

14 rue George Eastman

ZI Sud – 71100 Chalon-sur-Saône

contact@

protoformbourgogne.fr

Tel. 03 85 90 90 30

Plus d'informations sur

Linkedin

Linkedin

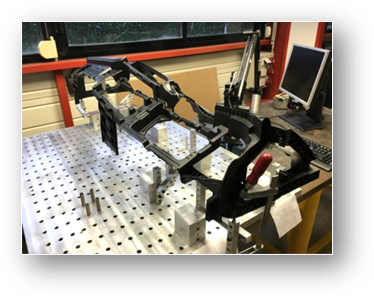

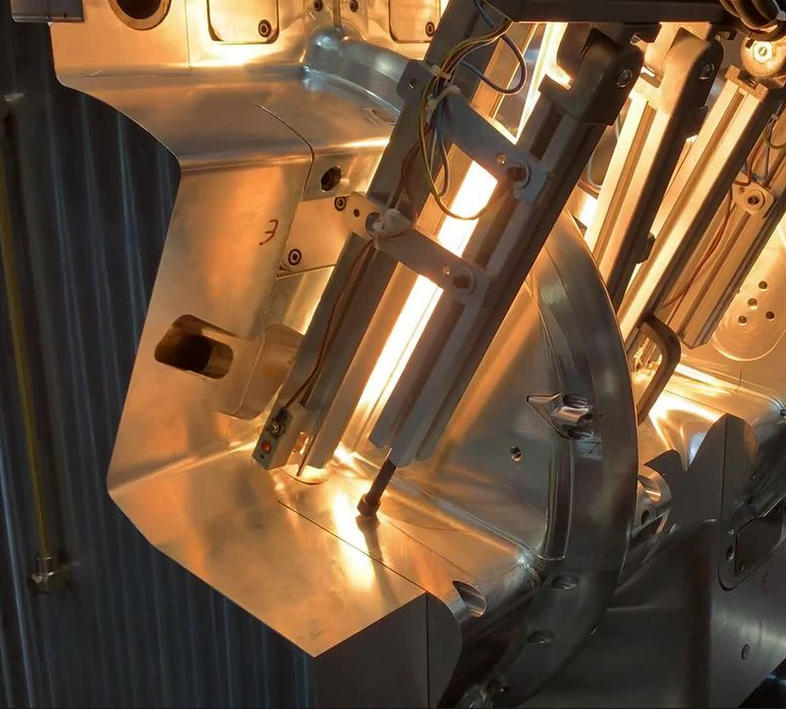

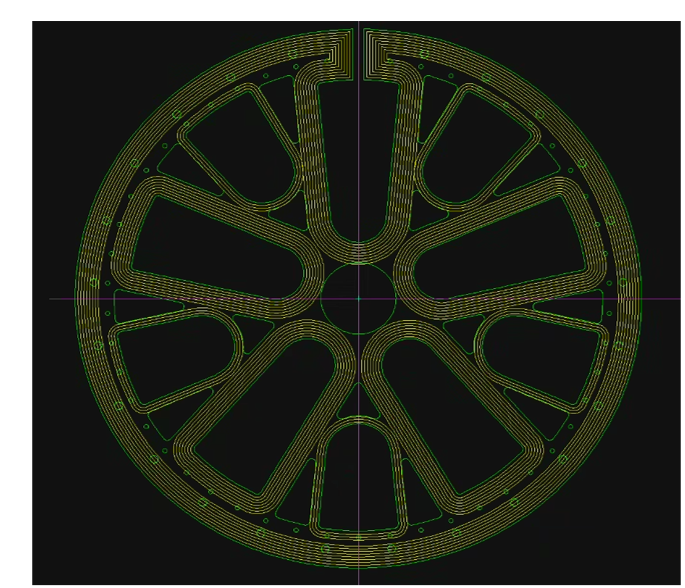

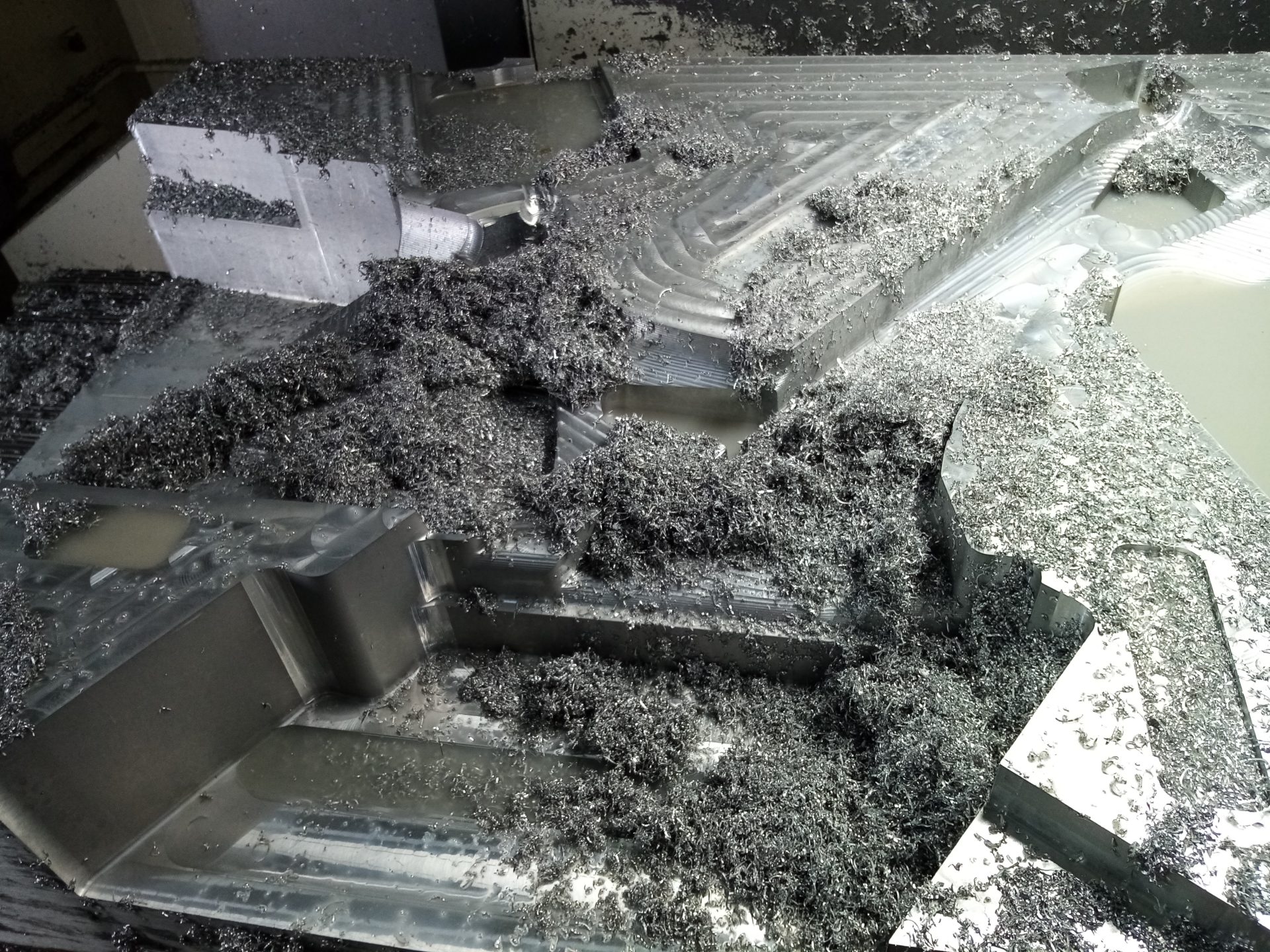

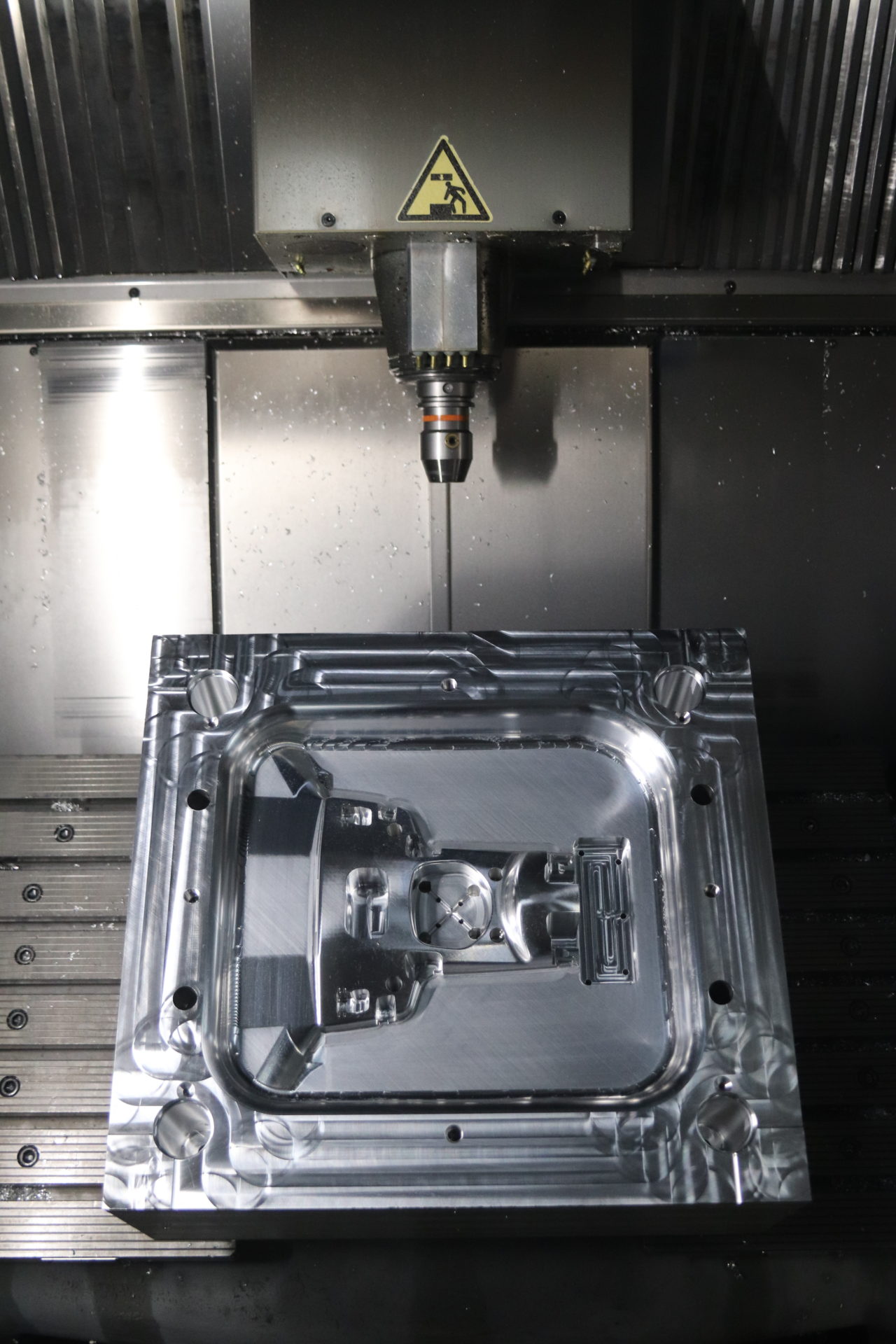

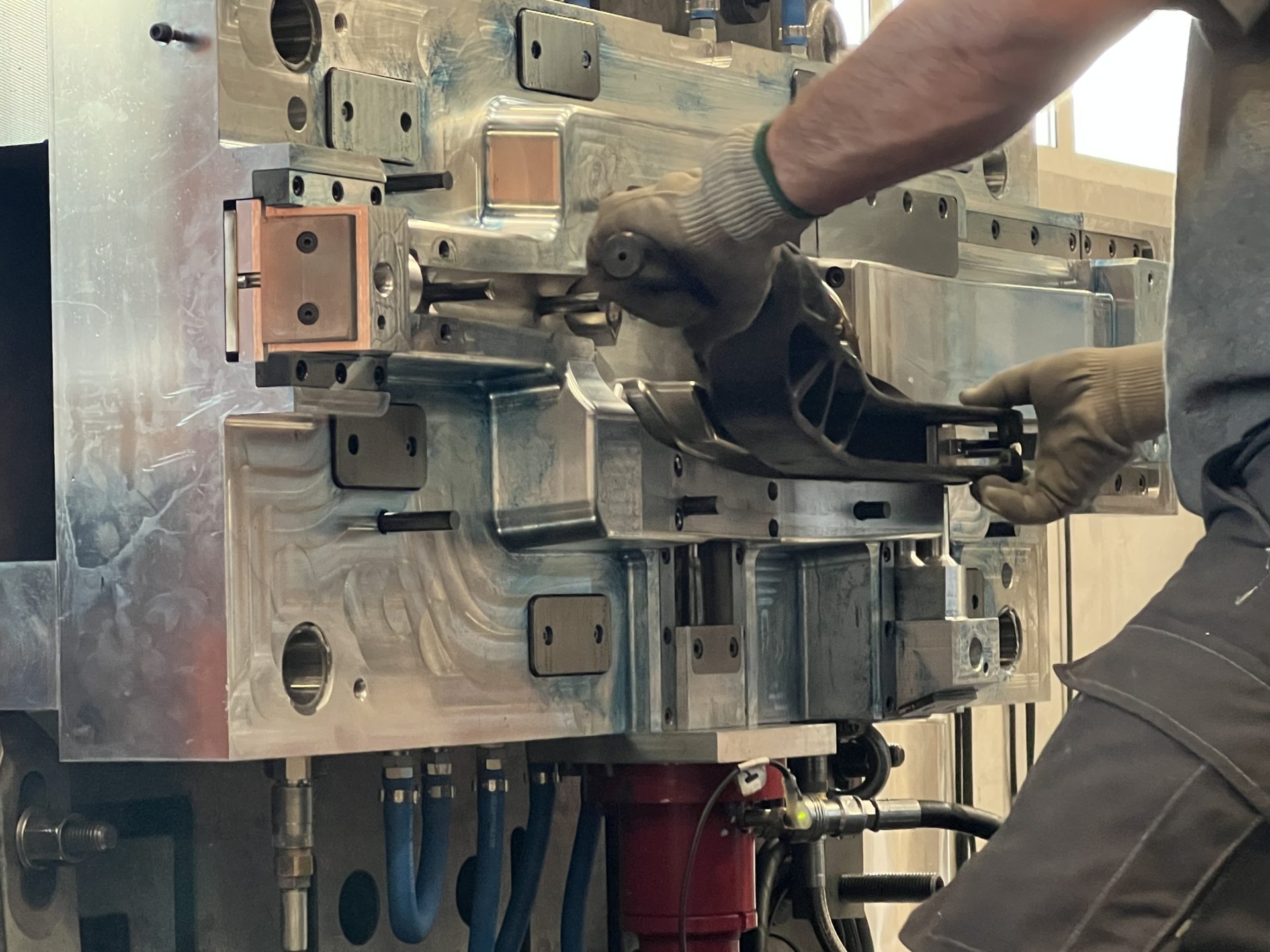

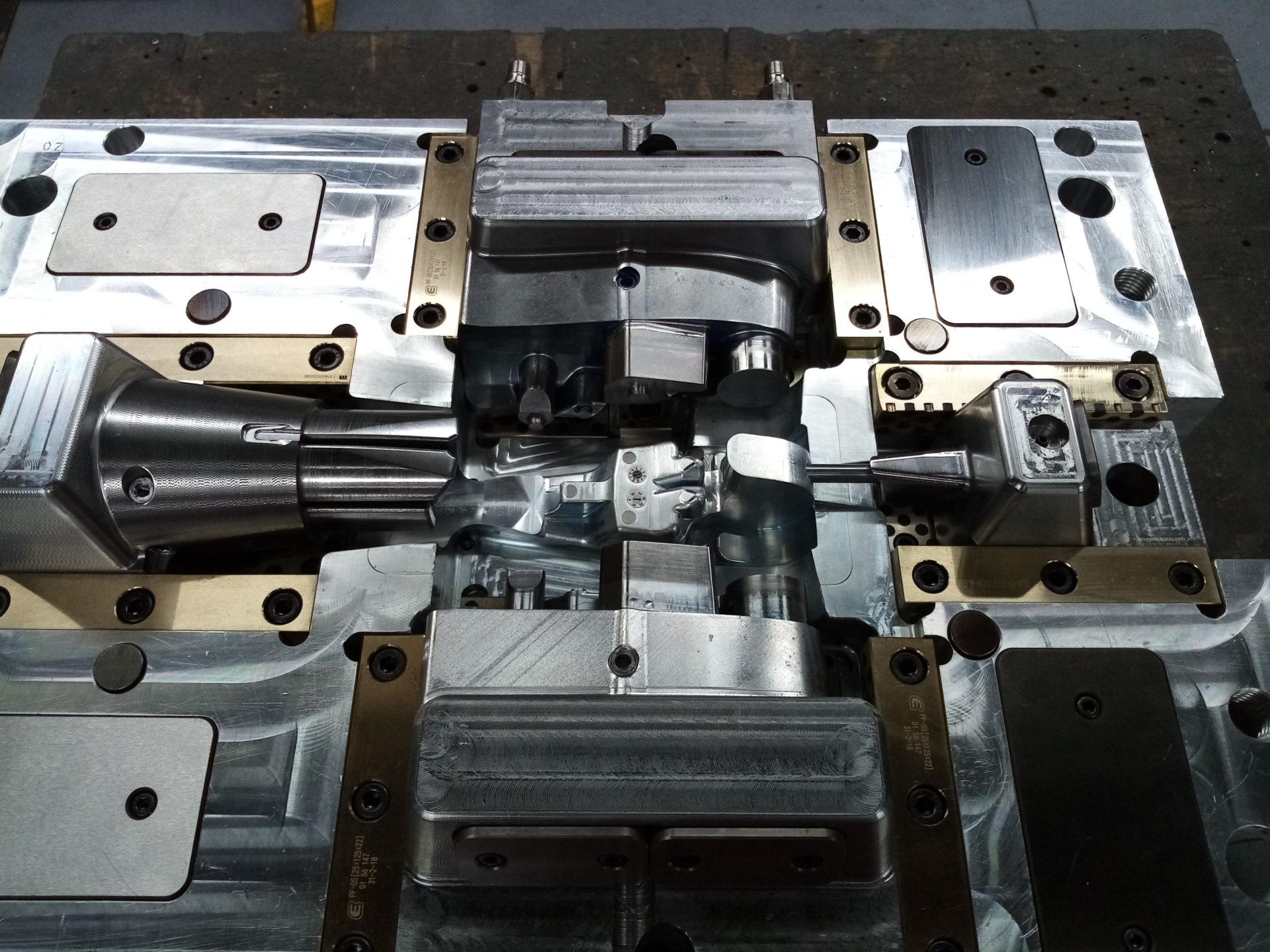

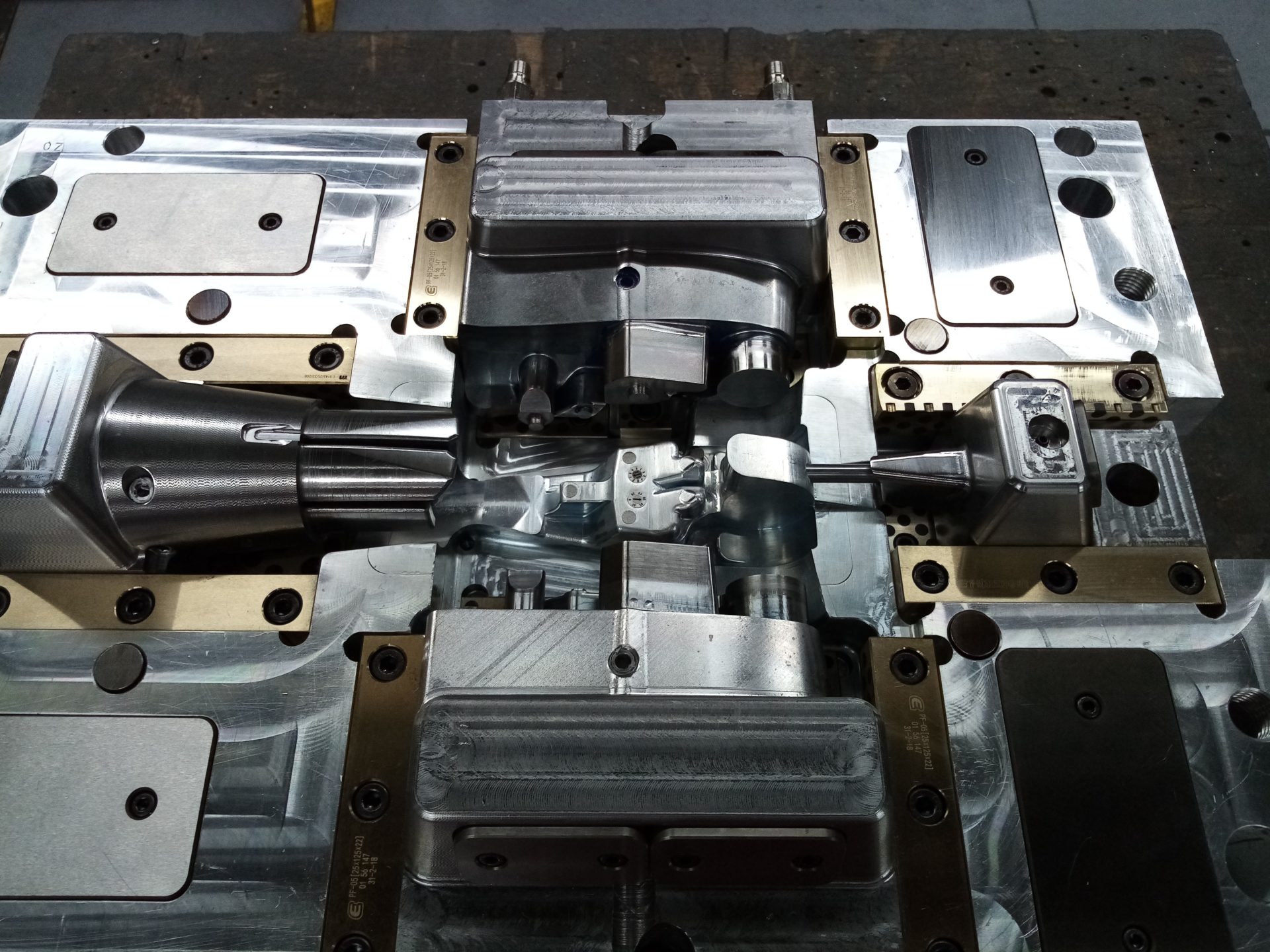

Petite visite d'usine

Protoform Bourgogne c’est…

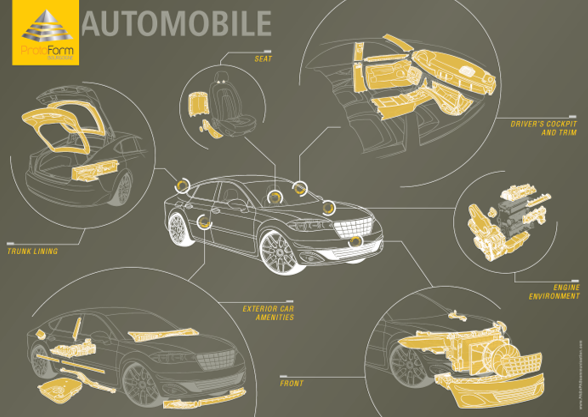

Nos marchés

Auto

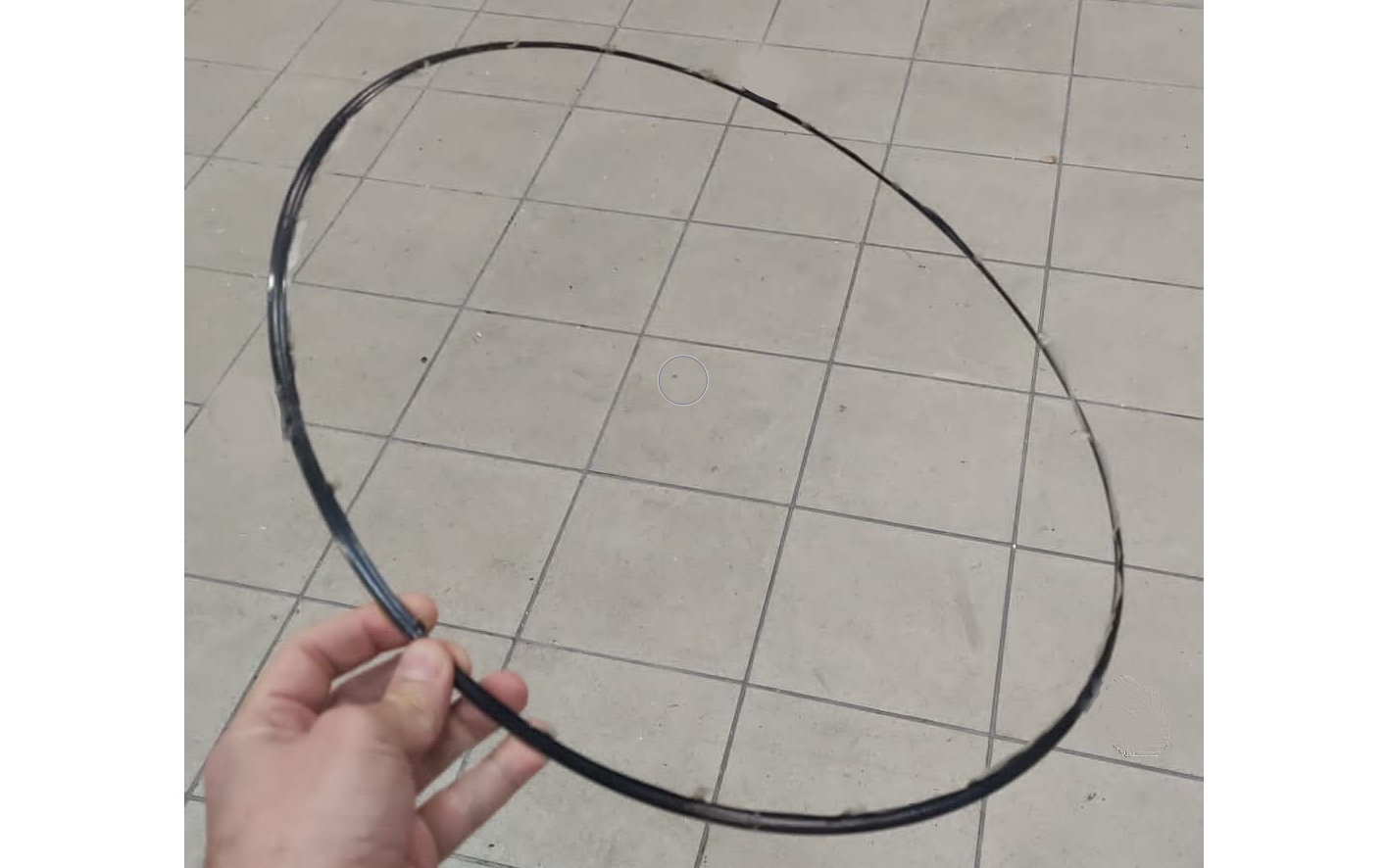

Vélo

Notre différence

Le SuperMoulage ®

Nos services

« De A à Z en MIF » Nous injectons et nous faisons les outillages, à 100% et en France

Injection petite et moyenne série